We went to W315 (we forgot to book but lucky us there's empty slot yay) and then we performed soxhlet extraction using the soxhlet apparatus provided. 200ml of ethanol was used to extract the oil from the rambutan seeds.

We used soxhlet extraction because it is a more

efficient method as compared to the use of mechanical press.

As soxhlet extraction uses the theory of

washing the sample over and over again with the use of the solvent, it has the

ability to obtain more bio-oil. Furthermore, soxhlet is able to isolate desired oil, which has

limited solubility in the solvent and the impurity is insoluble in a solvent.

Thus making the bio-oil have higher purity.

We used soxhlet extraction because it is a more efficient method as compared to the use of mechanical press.

As for the use of

ethanol, it was decided upon when the use of n-hexane was deemed too dangerous

to be used as the flash point was way too low, which may cause imminent danger

to the user. Ethanol is a safer solvent to use compared to n-hexane. We don't wanna die yet, we're too young.

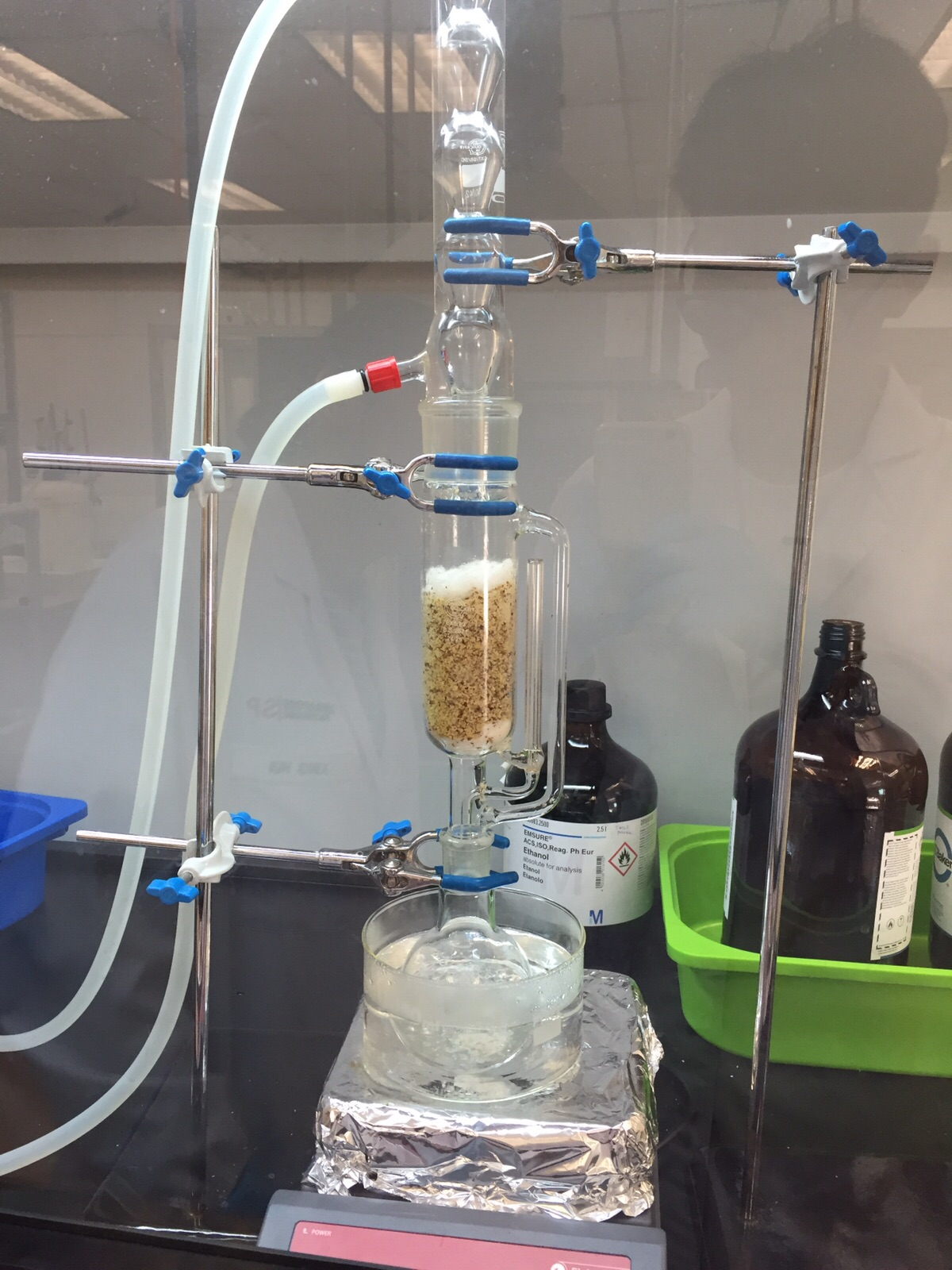

The experimental setup is shown below.

Ethanol was heated so that it can be vaporised, it is being heated through water bath as the round flask heater was faulty (take note).

This gif illustrates the intended process of soxhlet extraction. Ethanol vaporises, then condenses on the seed stack. Condensed ethanol is collected, and when the return tube is full, the seed stack is submerged, the reservoir will fall back to the flask.

We did soxhlet extraction for about 2 hours then we noticed that there wasn’t any significant differences. Progress was very minimal. The ethanol was supposed to vaporise and then condense back, and cause the seed stack to become wet. We noticed ethanol condensing but it was only a few droplets even after two hours. Wow we could've used the two hours to do so much other things but alas

We suspected that the cotton layer was too thick (sometimes you shouldnt 'play safe' too much by adding too much), hence we removed a huge portion of it.

Due to the thick

cotton layer, all the condensing ethanol is soaked in by the cotton, thus, only

little ethanol is able to come into contact with the Rambutan seeds.

Hence, when the cotton layer is reduced, ethanol is able to pass through easily and perform

leaching. The time of the process is also significantly reduced.

After which, ethanol was able to condense at a fast rate. Finally we weren't waiting so much for nothing!

We took around 6 hours to complete soxhlet extraction. In the meanwhile, we spent hours doing things and talked about almost anything. Other than that we were on our phones on social medias, we keep refreshing our timelines in the hope of seeing new posts, we bugged other busy people on Whatsapp, trying to talk to them, we walked around campus on an expedition (we took turns in shifts) just to pass time and we watched horror movies (yes in bright daylight). We monitored the process in the meanwhile of course.

We managed to do six cycles of soxhlet extraction. A total of 8 hours were spent.

A cycle is completed when the return tube is completely full, the seed stack is completely submerged with condensed ethanol, and then the return tube will empty itself along with the seed stack. The liquid reservoir on the seed stack will flow down to the round-bottom flask that contained ethanol.

During the sixth cycle, the solvent at the sight glass started to become quite clear, hence, we decided to stop the experiment. Finally we're done for the day. But nope, tomorrow still need go lab. At least soxhlet extraction is done!